La capacità di una vite di comando di una macchina utensile Per operare in modo efficiente e senza inceppamenti 24 ore su 24, è necessario principalmente l'effetto sinergico di tre fattori: progettazione e selezione adeguate, lubrificazione e manutenzione adeguate e controllo ragionevole delle condizioni operative. Nello specifico, questo può essere suddiviso nelle seguenti dimensioni chiave:

1. Progettazione strutturale e processo di produzione ad alta precisione

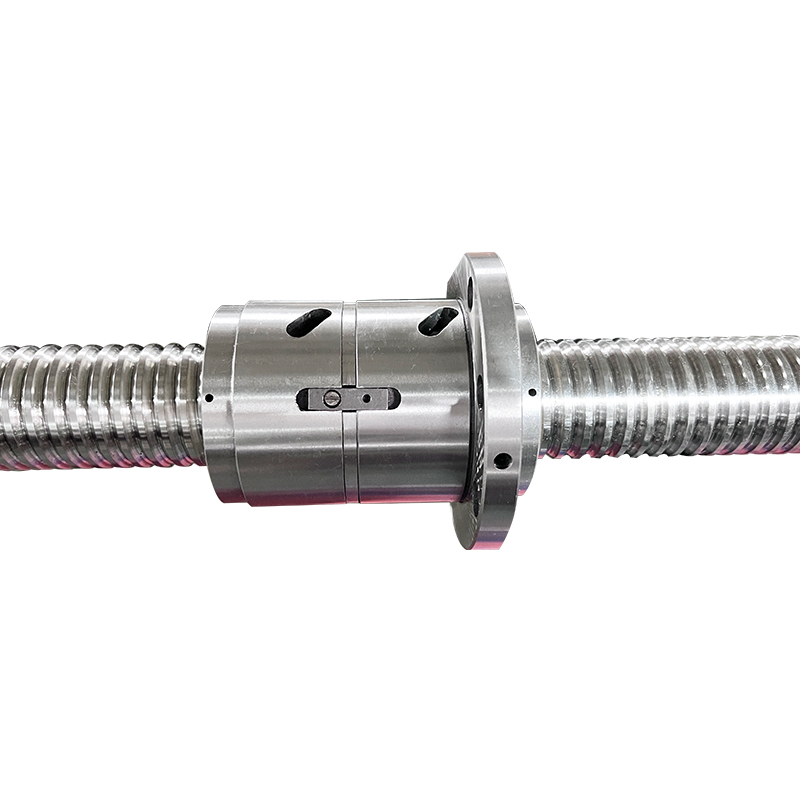

Adattamento di precisione della coppia di trasmissione: viti a sfere utilizzano sfere d'acciaio come elementi volventi. Rispetto al contatto superficiale delle viti a strisciamento, si tratta di un contatto puntiforme, con un coefficiente di attrito estremamente basso (solo da 1/10 a 1/3 di quello delle viti a strisciamento). Ciò comporta una bassa resistenza all'attrito e una minore generazione di calore durante il funzionamento, prevenendo inceppamenti causati da surriscaldamento.

Il processo di precarico elimina il gioco: una struttura di precarico a doppio dado (come il tipo a rondella, il tipo a passo variabile o il tipo filettato) elimina il gioco assiale tra vite e dado di comando, garantendo la precisione della trasmissione e prevenendo movimenti assiali e inceppamenti durante il funzionamento ad alta velocità.

Materiali di alta qualità e trattamento termico: Le viti e i dadi conduttori sono in genere realizzati in acciaio ad alto tenore di carbonio (come GCr15) o acciaio strutturale legato, trattato con tempra, rinvenimento e rettifica per ottenere una superficie durezza HRC58~62. Ciò si traduce in un'elevata resistenza all'usura, prevenendo usura e deformazione durante il funzionamento a lungo termine e mantenendo una precisione di adattamento stabile.

2. Sistema di lubrificazione e tenuta stabile e affidabile

Lubrificazione continua ed efficiente:** dotata di un sistema di lubrificazione automatico (come una pompa per grasso o un dispositivo di lubrificazione a nebbia d'olio), rifornisce la pista della vite madre con grasso o olio specializzato a intervalli regolari, formando una pellicola d'olio che riduce l'attrito diretto tra le sfere in acciaio e la pista, riducendo l'usura e la generazione di calore. Le macchine utensili che funzionano 24 ore su 24 sono generalmente dotate di lubrificazione automatica intermittente per prevenire una lubrificazione insufficiente o l'invecchiamento del grasso.

Eccellente protezione di tenuta:** Entrambe le estremità della vite madre sono dotate di guarnizioni antipolvere, piastre raschianti e altri componenti per impedire l'ingresso di fluido da taglio, trucioli metallici e polvere nella pista di rotolamento. Le impurità che penetrano nella pista di rotolamento sono una causa comune di inceppamento della vite madre; il sistema di tenuta isola efficacemente i contaminanti e mantiene pulita la pista di rotolamento.

3. Parametri operativi ragionevoli e controllo del carico

Corrispondenza tra carico e velocità: durante la selezione, i carichi dinamici e statici nominali della vite madre vengono determinati in base al carico effettivo della macchina utensile (forza di taglio, peso della tavola) per garantire che il carico non superi il valore nominale durante il funzionamento di 24 ore, evitando la deformazione dei cuscinetti a sfere e la flessione della vite madre dovuta al sovraccarico. Contemporaneamente, la velocità viene controllata al di sotto della velocità critica della vite madre per prevenire risonanze e vibrazioni durante la rotazione ad alta velocità.

Controllo della temperatura: la macchina utensile è dotata di un sistema di raffreddamento per controllare la temperatura di esercizio della vite madre e del mandrino. Il riscaldamento della vite madre può causare deformazioni termiche, con conseguenti variazioni di passo o persino inceppamenti. Il sistema di raffreddamento è in grado di controllare le fluttuazioni di temperatura entro un intervallo minimo, mantenendo la stabilità della trasmissione.

4. Coordinamento preciso dei sistemi di azionamento e controllo

Collegamento rigido tra servomotore e vite conduttrice: i giunti (come giunti a membrana e giunti lamellari) vengono utilizzati per ottenere un collegamento senza interruzioni tra il motore e la vite conduttrice, garantendo una trasmissione di potenza fluida ed evitando strappi nella trasmissione causati da collegamenti allentati.

Regolazione precisa del sistema CNC: tramite un sistema di controllo a circuito chiuso o semichiuso, la posizione e la velocità della vite madre vengono monitorate in tempo reale e la coppia di uscita del motore viene regolata dinamicamente per compensare la deformazione elastica e la deformazione termica della vite madre, garantendo una velocità uniforme e nessun impatto durante il funzionamento.

Supplemento: Il ruolo cruciale della manutenzione ordinaria: anche in condizioni di progettazione e funzionamento ragionevoli, una manutenzione regolare è essenziale per un funzionamento ininterrotto 24 ore su 24, 7 giorni su 7. Ad esempio, la pulizia regolare delle guarnizioni, il controllo delle condizioni del grasso lubrificante, il rilevamento di eccentricità e gioco della vite madre e la sostituzione tempestiva del grasso vecchio e delle sfere usurate possono prolungare efficacemente la durata di funzionamento stabile della vite madre.